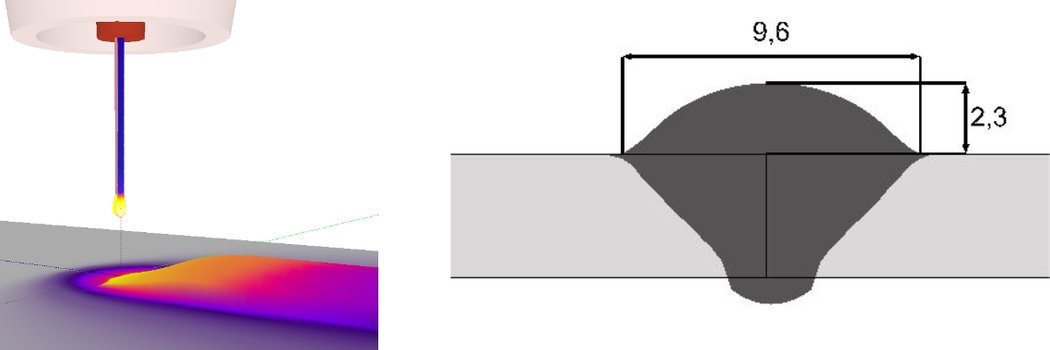

Welding process simulation, also known as welding process analysis, maps the formation and progress of welding, primarily in the seam area. This simulation aims at the prediction of the seam formation. The heat input is determined predictively. The welding process simulation considers all welding processes such as:

Welding process simulation allows us to accurately determine the design of process parameters, predetermine weld properties and calculate heat input for assemblies for our customers.

A characteristic feature of the weld structure simulation is that the heat input during the simulation is not calculated predictively but is specified as an input variable in the form of an equivalent substitute heat source. With the weld structure simulation we calculate for our customers the temperature field, the weld distortion, the residual stresses and the microstructure on the complete component or on assemblies. The weld structure simulation considers all welding processes such as:

We are happy to offer weld structure simulation for brazing processes, build-up welding processes or additive manufacturing processes. These numerical calculations are often used for special questions in the fields of mechanical engineering and automotive industry.

With this simulation method all welded materials and material alloys can be calculated:

With weld structure simulation, we can precisely determine the effects of welding sequence or clamping situation on the final condition of the component. Optimization measures and compensation measures can thus be designed.

Using highly sophisticated multi-stage calculations and process chain simulations, we offer calculation of the entire manufacturing process, including other manufacturing processes such as forming or heat treatment for industry.

© Dr. Loose GmbH, alle Rechte vorbehalten | Impressum | Datenschutz | Rechtliche Hinweise